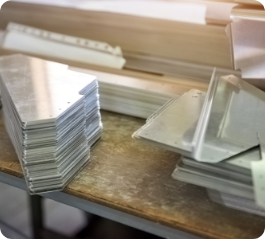

Sheet Metal Design Services

We offer a full in-house design service from conception to production drawings. We have a team of full time draughts people on site at our manufacturing facility, using industry leading design and analysis software.

We work closely with our customers to ensure that their vision gets materialised as accurately and flawlessly as possible.

Key Features of Our Sheet Metal Design Services

Our products are designed and fabricated all under one roof which allows us to tune our designs to maximise the potential of our machinery. We accurately calibrate our machines daily to ensure quality.

Since all of our products are completely designed, cut, formed and fabricated in our factory, we can change design elements and parameters at will allowing customers to customise everything.

Quality Assurance

Quality control is an essential component of our production process.

We diligently examine all of our materials and will reject anything that does not meet our standards.

FAQ

What’s involved in the sheet metal design process?

Our clients journey with us starts with a design consultation. It is important to outline the key aspects and requirements of the jobs while discussing the endless possibilities we can offer. Our next step is to get the first version of technical drawings to the customer and get the production process underway. The first prototype and stringent quality control measures are essential for our customers’ quality assurance. Once the first prototype is approved we evaluate the entire process into our production planning and try to outline an estimated production time and delivery timeframe.

What types of industries do you typically work with for sheet metal design projects?

Our main client base is with architects and engineers and contractors. We liaise mostly with these personnel as they are essential in the design process and early stage of any project.

What software/technology do you use?

We use the latest Computer Aided Design software for accuracy and efficiency. We utilise software to most efficiently maximise the output of products from our material with minimal waste to reduce waste, environmental impact and cost to our customers.

Do you recommend the best materials for the project?

Our expert design and fabrication team would recommend our clients the best material for their project optimisation. If we do not stock the best quality material or a particular material , our skilled procurement team will source the best material externally. We go above and beyond for our clients.

What’s the typical turnaround time for a sheet metal design project?

Depending on the size and complexity of the project, it could take anywhere from a day to a couple of weeks to turn a project around.